Project Description

- Mission

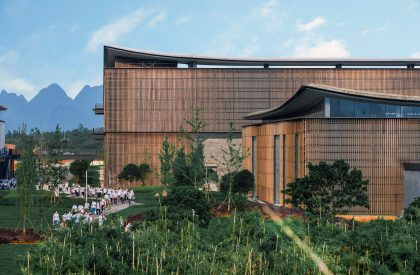

[Text submitted by the Architect] Integral is located in the Jiumeiqiao District of Guilin in Guangxi Province. The total area of the first and second phases of the project stretch over a 511,800 square-metre site. The first phase was completed in 2019, and the entire project is expected to be completed by the end of 2020.

The development of Integral has been driven by Esquel, a leading textile and apparel manufacturer. Their vision was to change the traditional image of textile manufacturing being a “low-tech” processing industry by integrating conservation elements with the concept of sustainable development in a new, state-of-the-art specialty spinning and garment manufacturing plant located in a scenic natural area: Guilin, China. The facility is more than a manufacturing plant, it is an industrial eco-tourism park which embraces the fundamental concepts of Buddhism and which has sustainability elements woven into every aspect of its design.

- Concept

Esquel believes that enterprises can, and should, play a critical role in protecting the environment. The architectural design of this project embodies several sustainable principles: “restoring land”, “recycling water”, “replenishing resources”, “harmonising people” and “nurturing local plant and animal species.” To reduce the environmental impacts of the project, the project combines advanced textile industry technology with an eco-tourism experience. The intent is to advocate that humans should maintain a humble attitude towards nature and not strip the earth of its riches – ultimately achieving the ideal state of “nature and humanity co-existing in harmony.”

- Planning

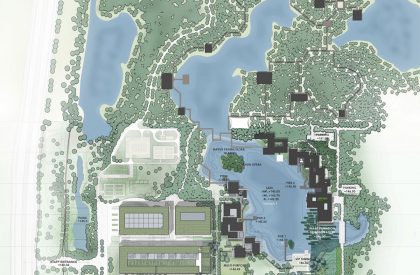

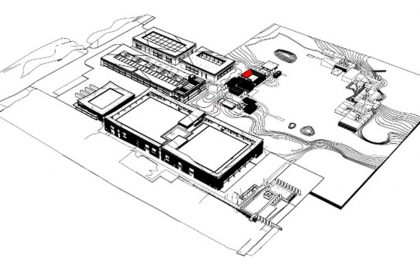

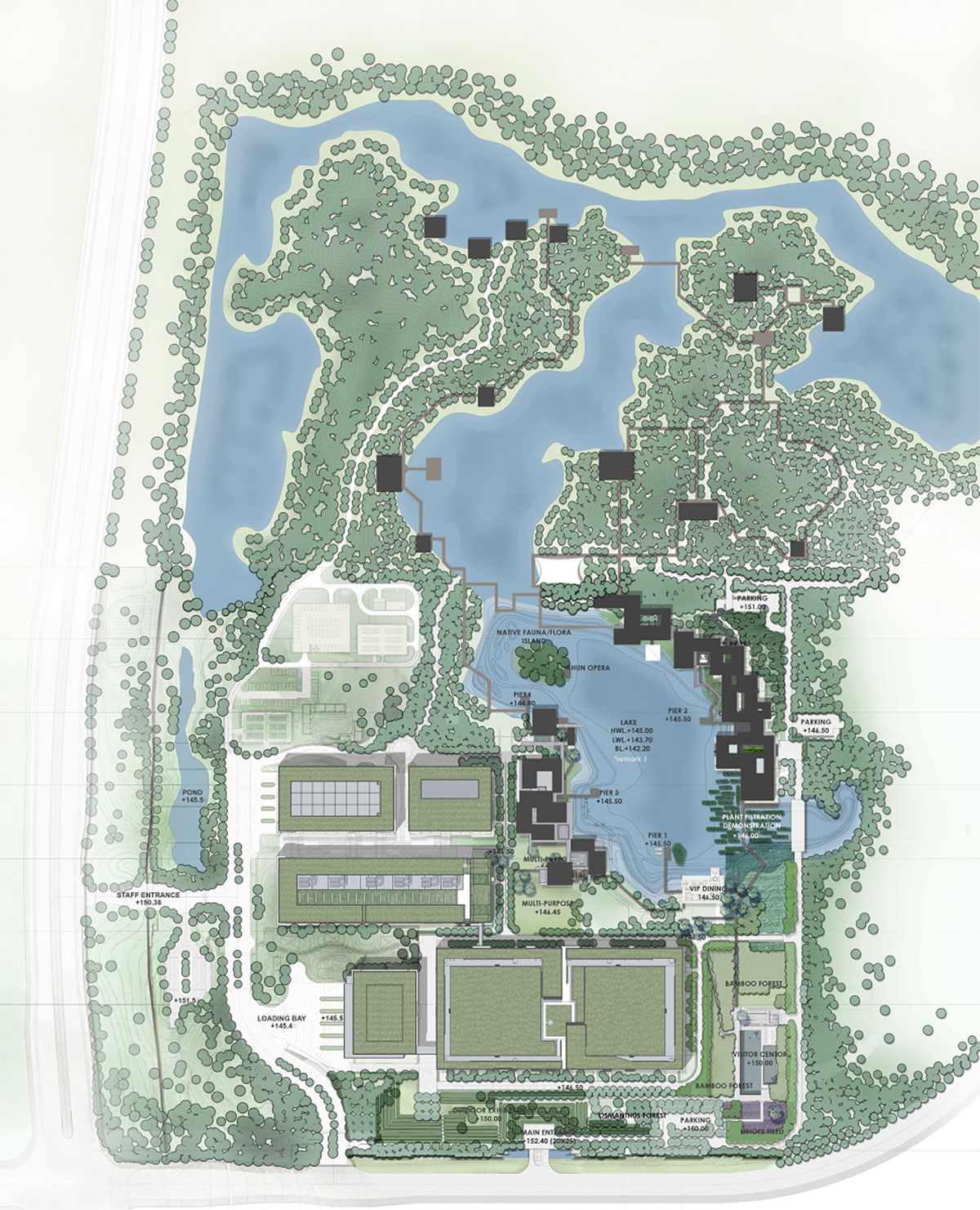

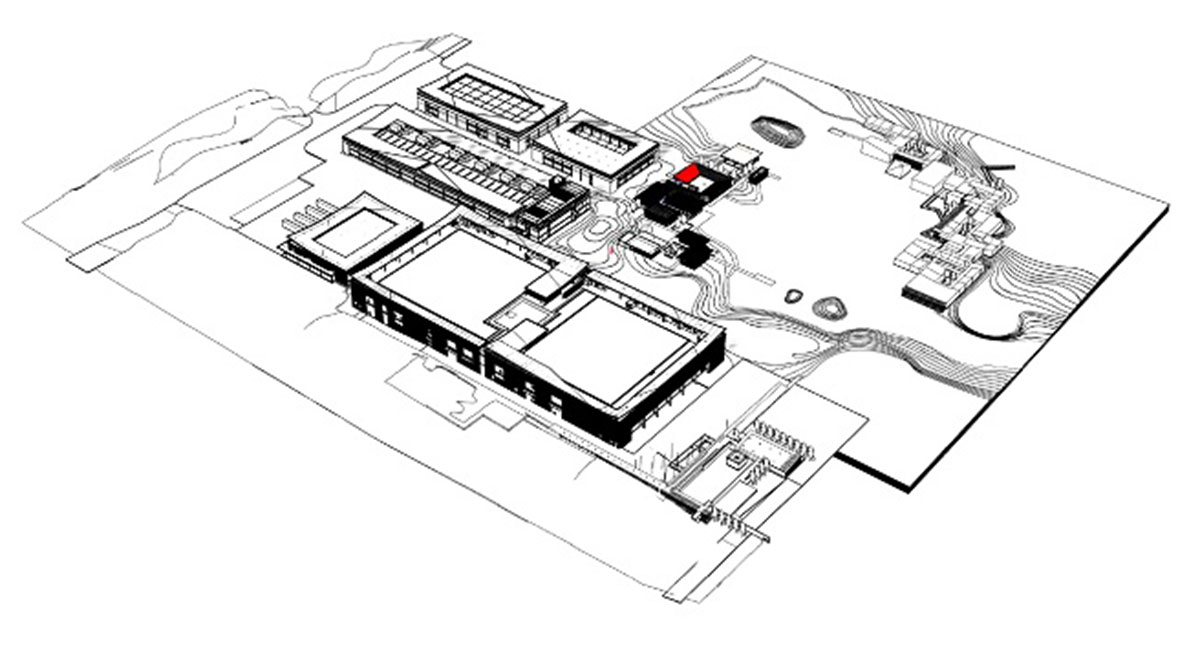

The design of Integral began with studies of the site’s topography and geology. The history and culture of Guilin and the local characteristics of the site were also referenced. The overall plan was to turn this manufacturing-centric area into a brand new conservation-led development. The design artfully combines three industries on one site: manufacturing, tourism and agriculture.

Next, the RLP team restored part of the existing industrial site to its original wetland landscape. This area acts as an entry point to the site. The team then placed large building blocks on the expansive dry area at the south side of the site which had been degraded by long-term excavation caused by the old factory’s activities. The idea was to retain the site’s ecology as much as possible, including the bamboo groves, fish ponds and wetlands on the north side of the site. RLP worked hard to restore the site’s original lake and then placed small-sized buildings along the lakeshore, designed to echo the design of the buildings to the south yet respect and remain in harmony with the lake.

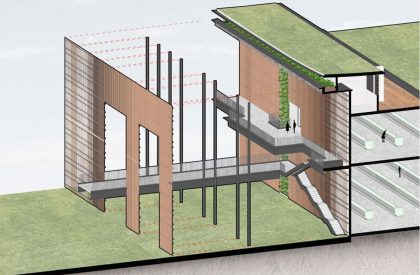

The highest point of the entire project is only 22 metres in elevation. The design intentionally extended the main building horizontally instead of vertically, seamlessly integrating the large production workshop and craft centre with the natural environment. In turn, this makes the site’s greenery the main focus, with the buildings playing a supporting role in the overall aesthetic.

- Materials selection

The building materials chosen for any project are a direct representation of the culture and technology of the era. Steel and concrete are the main building materials in most modern construction projects, signifying in some ways the erosion of cultural diversity due to economic globalisation. As a result, the homogeneity of materials and styles are a common dilemma faced by projects looking to revive traditional oriental architecture and embrace authentic regional culture.

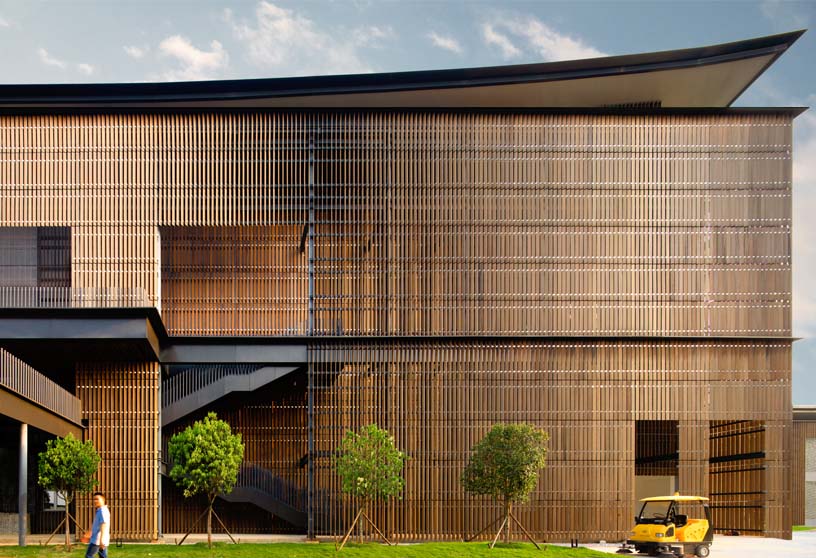

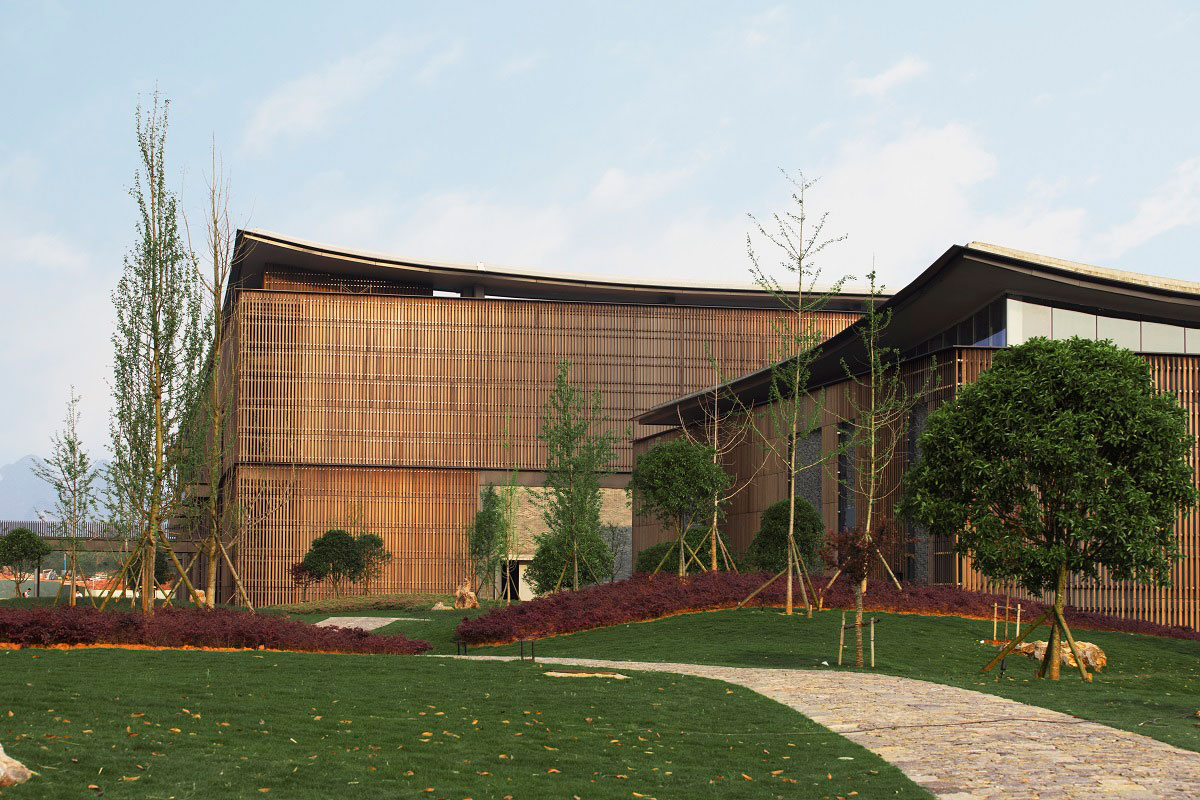

For this project, the RLP design team devoted themselves to the study of the local folk culture of Guangxi Province. During their investigations, they discovered that blue bricks and grey tiles were extensively used as building materials for the houses in the area’s ancient villages, with bamboo panels and strips commonly appearing in their daily lives. The architects these used these unique local blue bricks and recycled bamboo strips for the outer surface of the main building. By doing so, they not only paid tribute to traditional building techniques, they also put sustainable development into practice and lowered the project’s environmental impact by “turning trash into treasure.”

- Function

Apart from the core textile workshop and craft centre, the project also features botanical gardens, plantations, exhibition halls, staff restaurants, learning centres and other facilities. Upon the completion of Integral’s second phase, a retail commercial area and a performance centre will open, to further enrich the experiences of employees and visitors alike.

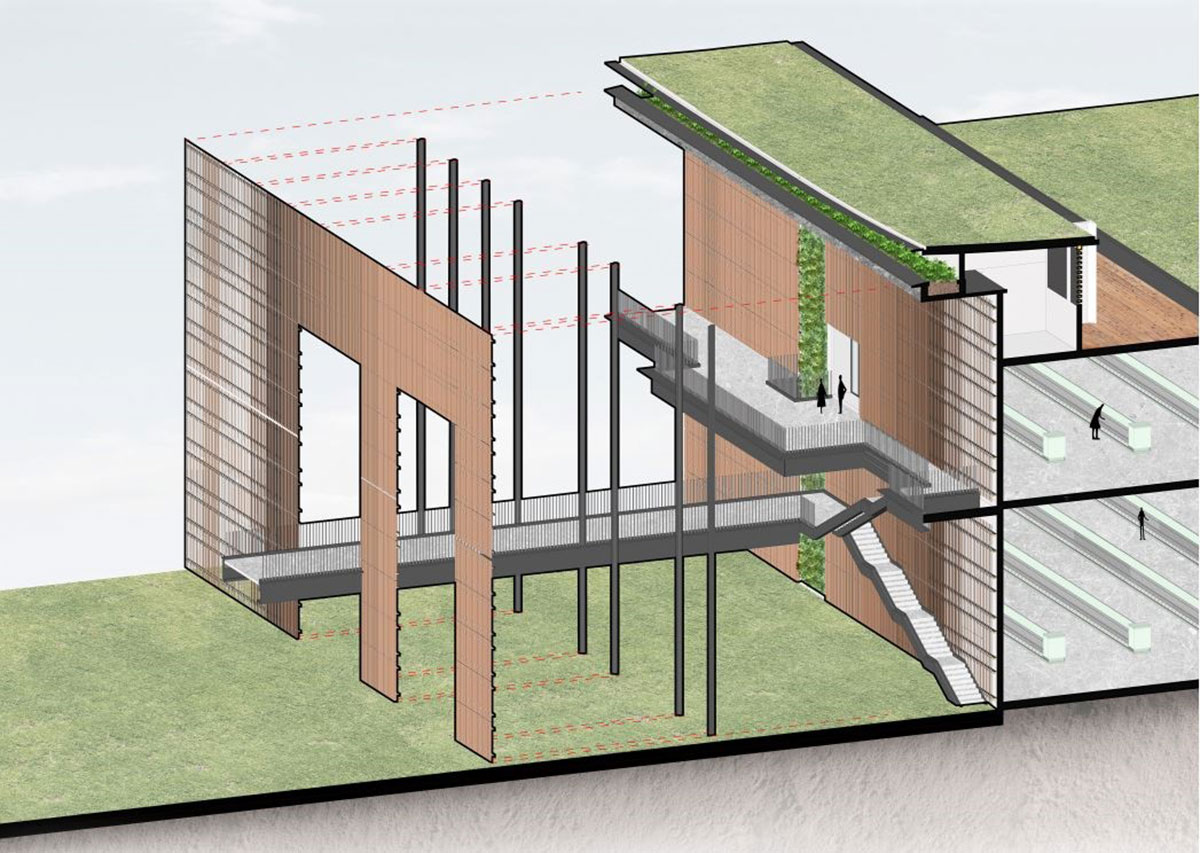

Additionally, a large percentage of the craft centre’s roof is covered with green plants, which not only increases the overall greenery coverage of the site, it also helps to insulate the building and keep the indoor temperature stable. Some of these plants are also part of a rooftop farm, which will provide fresh organic produce for the staff restaurant.

- Façade

The architects added a semi-transparent bamboo curtain with a gradient to the façade of the craft centre’s blue brick wall, creating the effect of a window screen covering the wall. The curtain smoothly merges with the surrounding trees and flowers and also softens and breaks up the long exterior façade of the building, making the factory appear more humble and in harmony with the natural environment.

© Ray Chen + Partners Architects

- Ventilation

The five main buildings of the first phase are located at the south side of the site, making the overall layout as wide as possible and effectively facilitating the penetration of southern winds in the summer. The semi-closed bamboo façades enhance these breezes to create a more comfortable experience in the heat of summer; while in winter, the restored hill slopes become a natural screen that blocks the cold northeast winds.

- Green Axis

All staff and visitors to the site pass through a leafy green walkway, an axis which runs through the entire site. This was purposefully designed to lighten the mood of staff on the way to and from work, and to create a stunning and naturally beautiful avenue for visitors to enjoy.

- Transparency

The architects skilfully utilised a “transparent” design strategy, using glass walls to strengthen daylight and improve visual connectivity with the factory floor, display centre and employee restaurant. To further achieve a visual connection effect, the borders between architecture, courtyards and nature were made deliberately vague, blurring the definitions of indoor and outdoor spaces.

- Vision

At its heart, Integral is a human-centred project that has the utmost respect for nature. RLP firmly believes that the concept of sustainable building development should revere the natural world, and that sustainable architecture should both co-exist with and be integrated into nature. This unique factory was also designed for the employees, to create an ideal working environment where they can be creative and contribute to the company and society.

Through a considered design concept and precise techniques, the design team ensured that every detail of the project responded to the spirit of craftsmanship championed by Esquel Textile Factory and their drive to create excellence. Every landscape plan was integrated with Guilin’s poetic, inspirational natural landscape; every innovative practice mutually reinforced the ethos of sustainable development advanced by the Esquel Group. Together, RLP and Esquel are pursuing a corporate vision that integrates the user experience, product quality, building energy efficiency, and environmental protection.