Excerpt: Woven Screen Office is a workplace designed by the architectural firm Takashi Niwa Architects. The “Woven Screen” is a modern take on traditional Vietnamese perforated terracotta block walls to optimize the interior airflow environment and light condition and create a space for better communication and creative working condition. Unlike traditional screens, this screen has no heads and tails. This demonstrates how the concept was realized, uniting space and people and sharing an ambiance.

Project Description

Woven Screen

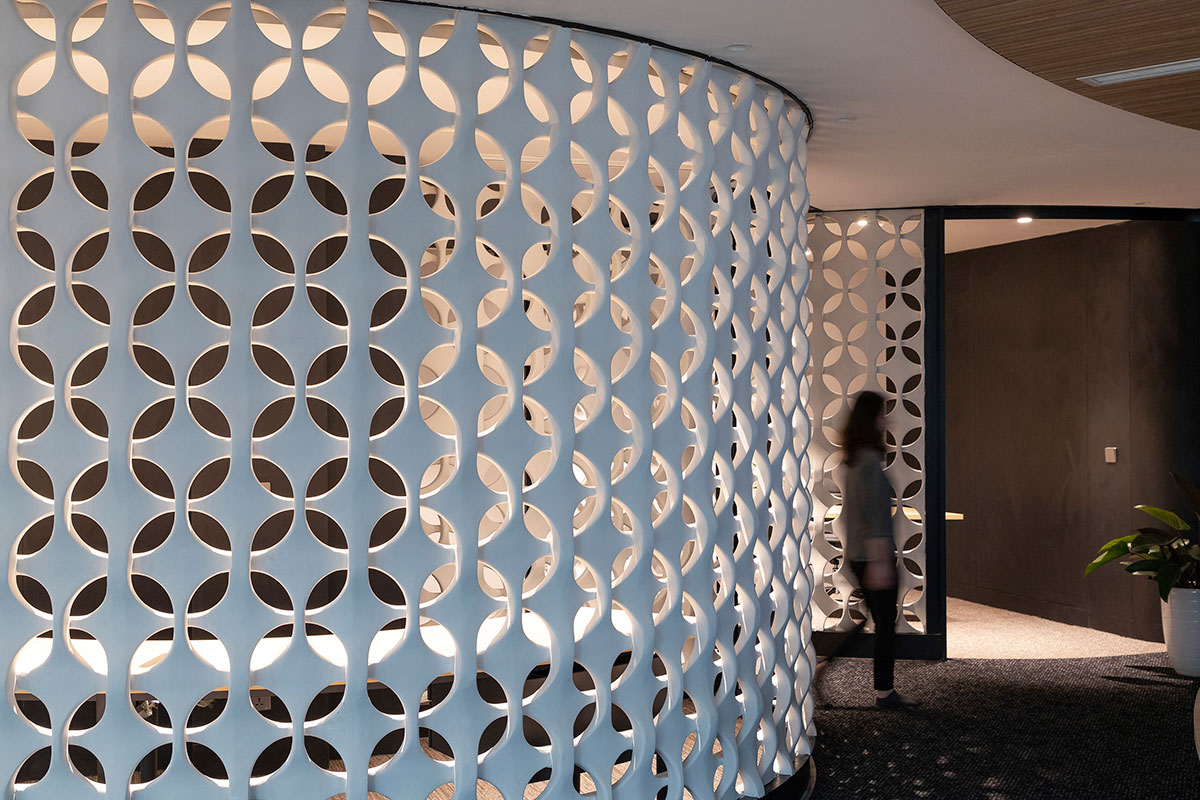

[Text as submitted by Architect] To achieve an “open yet enclosed, public yet private” space for an office interior in Hanoi, Vietnam, we propose a screen design with 3-dimensional concrete blocks. Traditionally, perforated terracotta blocks have been used for building facades in Vietnam to provide the best condition in tropical climates – blocking harsh sunlight while letting natural breeze comes in.

The “Woven Screen” is our modern take on traditional Vietnamese perforated terracotta block walls to optimize the interior airflow environment and light condition and create a space for better communication and creative working condition. Unlike traditional screens, this screen has no heads and tails. This demonstrates how the concept was realized, uniting space and people and sharing an ambiance.

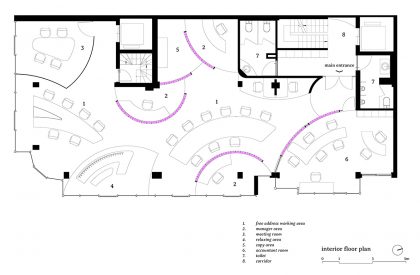

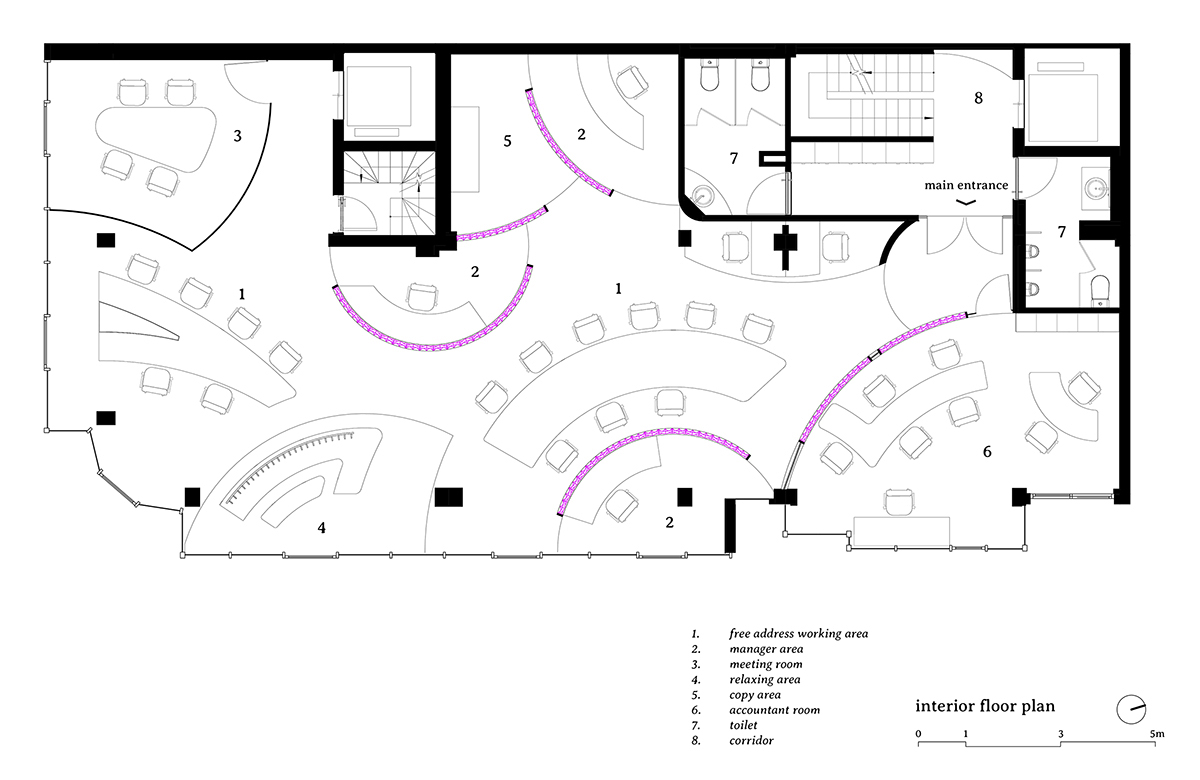

It is an office interior project accommodating 25 employees, including four managers from 4 different departments. The project floor consists of 3 separate buildings. Members of the client have been spreading over each floor of each building, which is not easily accessible to each other. This results in a lack of unity in the company and efficiency of the cooperation beyond the departments.

Therefore, the first main target of this project is to create a sense of unity by inducing better communication. Secondly, the work efficiency of each member and synergy between them. Thirdly, they needed a delightful atmosphere in this new office to inspire and motivate employees in their daily work.

For the reasons above, the working space is required not to be divided by the departments but open and connected, except for the accountant department for security reasons. The manager area needs to be semi-open for their confidential document and privacy.

The solution for the requirement was to provide a perforated wall to divide the space yet connect physically. It creates a special spatial experience with its opening and waving surfaces. Open yet enclosed, public yet private space was realized. Since each wall is curved, the area inside of the screen is covered. It blocks the view from a certain point, but from the front side, one can exchange eye contact and even hand over the document through the opening of the screen. Also, the wall’s stability is strengthened thanks to the curved wall.

Specific functions such as manager areas, printing area, accountant room, and meeting room are placed in corners. The rest of the space is turned into an open working space. Big tables for multiple users are shaped within the distance between the screens. The partly dropped ceiling roughly defines the working spaces, and the different floor finishes colors.

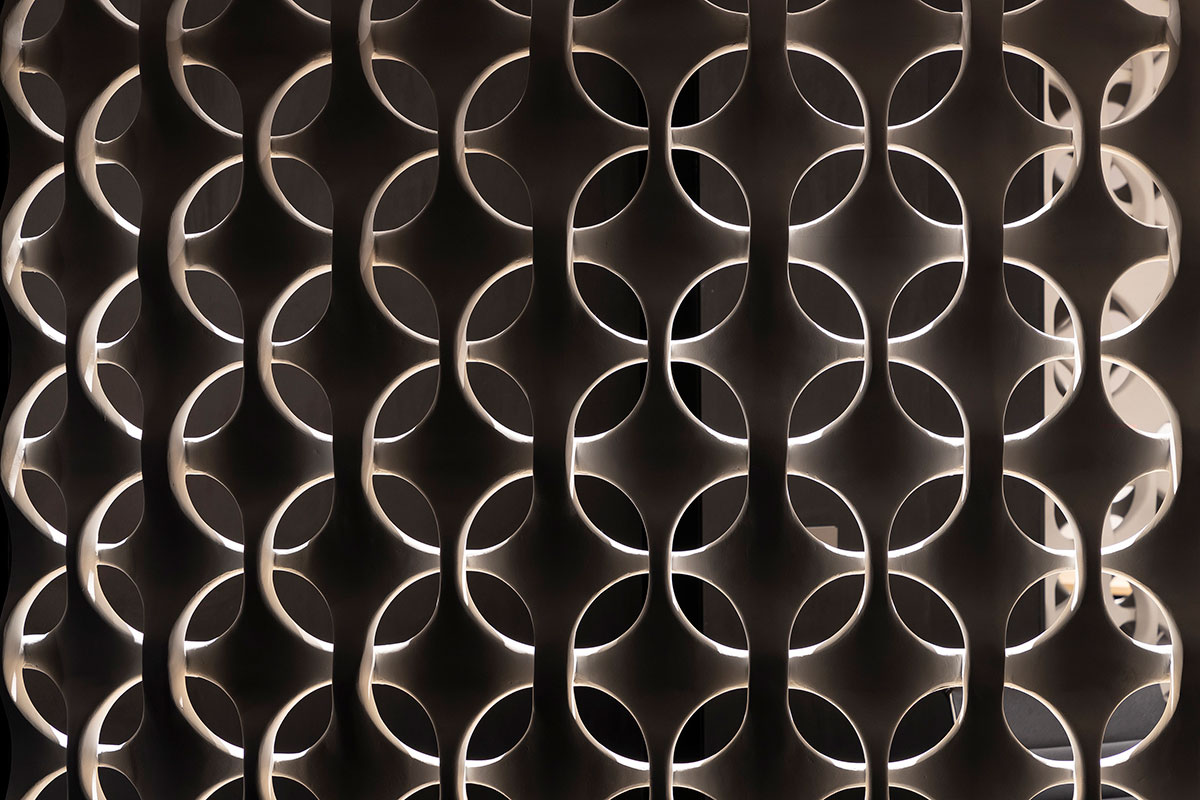

The perforated walls consist of the “Woven screen,” the 3-dimensional curved design modules. The module is a 280 x 280 x 160mm size concrete block. Along the vertical and horizontal 16mm steel frame, concrete blocks were stuck and fixed, the gaps were filled by mortar, and all the surfaces were polished.

3D printers were essential in realizing this complicated 3-dimensional curved surface design by concrete. One unit of 1:1 scale was divided into four pieces to be printed out by a 3D printing machine and assembled. Then it became the molding frame for casting concrete. After the completion of 1 unit, the factory started mass production.

One unit of the concrete block costs about 6.5 USD. Five hundred sixty pieces are used in this project. The total cost is around 3,640 USD. To locally fabricate new and original designs at an affordable price is a substantial benefit in Vietnam.

The lighting features highlight the woven screen, giving the space a sensational impression and inspiration. Not only for a working space but also to be a place to enjoy life and be inspired. Throughout this landscape of woven screens, open yet enclosed, public yet private space was realized.